What is Compressed Air And Is it Safe: A Complete Guide On Its History, Working, Applications 2024

Hey buddies! Han here and today I wanna ask you a question about the origins. What is compressed air and what history does it hold?

Have you ever wondered how compressed air works and why it’s such a vital component in our various industries?

All these answers lie here with you and me delving deep into the fascinating world of compressed air and exploring its many applications.

Now, compressed air often referred to as the “Fourth Utility,” is used in a wide range of industries, from manufacturing and construction to healthcare and automotive. But how does it work?

In this compressed air guide, you and I are going to break down the science behind compressed air, explaining the advantages of compressed air energy storage.

We will also explore the various applications of compressed air, and how it is used in different industries.

So, whether you’re a curious individual or a professional seeking to expand your knowledge, this guide is your go-to resource. Now, let’s dive in and uncover the power and versatility of compressed air together!

What Is Compressed Air?

Compressed air is the result of air being compressed and stored at a higher pressure than the surrounding atmosphere (atmospheric pressure). This is typically achieved using a compressor, which forces air into a storage tank.

What is Compressed Air Made of?

Compressed air same as atmospheric air is a mixture of gases. Both mainly consist of 78% nitrogen, 20 to 21% oxygen, 1 to 2% carbon dioxide, water vapors, and other gases. At the microscopic level, its molecules possess varying amounts of kinetic energy as they are always in motion.

Why Compressed Air is Hot?

When compressed, air molecules move more quickly, and the temperature increases. This results in a phenomenon known as “Heat of Compression” in which air is forced into a smaller space, bringing molecules nearer.

During this process, the released energy is forcefully stored in a smaller space i.e., a tank. So, it can be used in the future for performing a variety of tasks.

The History Of Compressed Air!

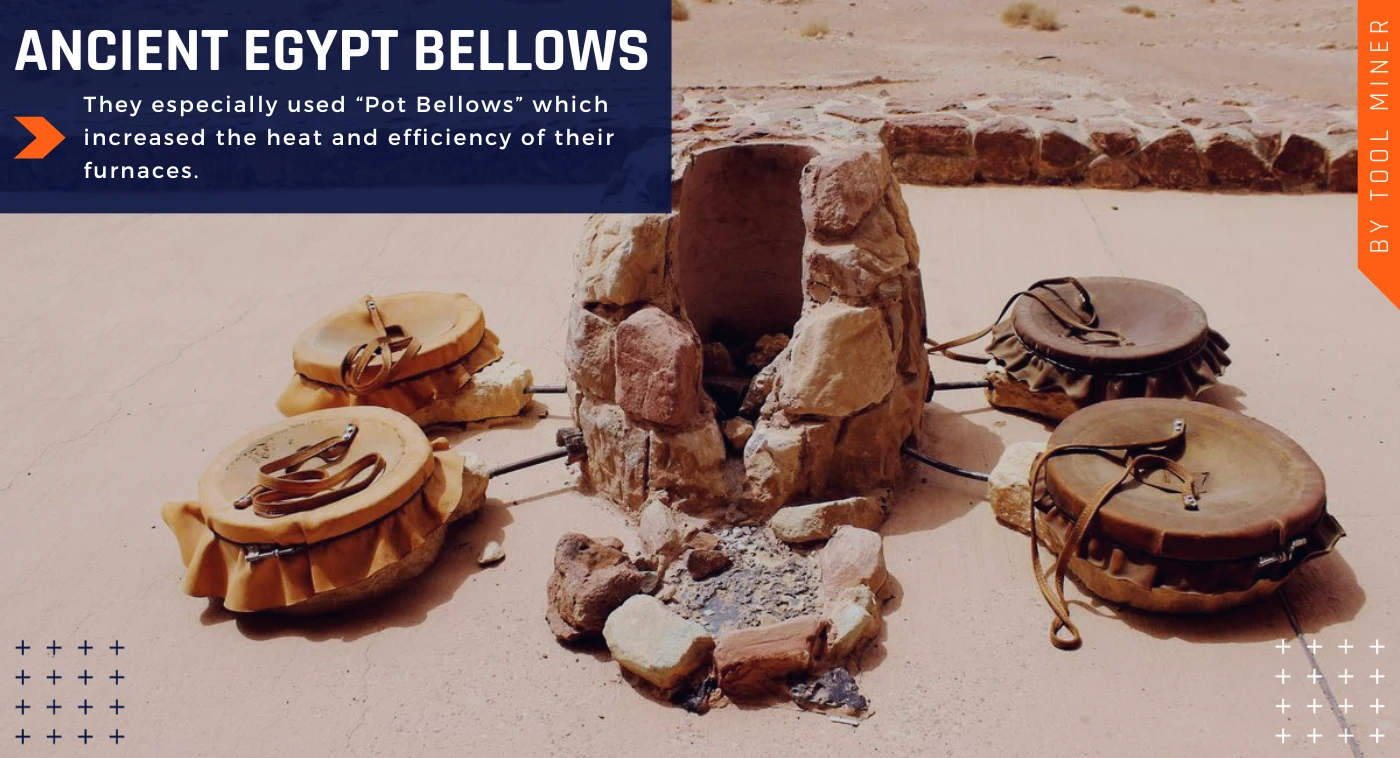

Ancient Egypt Bellows

The use of compressed air dates back centuries, with the first recorded use believed to be in ancient Egypt. The Egyptians used bellows to blow air into their fires. They especially used “Pot Bellows” which increased the heat and efficiency of their furnaces.

Evangelista Torricelli | The Barometer Inventer

In the 17th century, the Italian physicist Evangelista Torricelli invented the barometer, which relied on the principles of compressed air. This invention laid the foundation for further advancements in compressed air technology.

19th Century | Industrial Revolution

In the 19th century, compressed air began to be used for industrial applications—the development of more efficient compressors and storage systems allowed for a broader range of uses.

Compressed air became a popular choice for powering machinery, as it was safer and more versatile than other energy sources at the time.

How Does Compressed Air Work?

That’s the past and at present here I am gonna help you familiarize yourself with the basics of compressed air. So, you can comprehend how air compressors operate and are utilized on job sites.

The compressor works by reducing the volume of air, which in turn increases its pressure. Once it reaches the desired pressure, the compressed air is stored and ready for use.

Compressed air is distributed through a network of pipes and hoses to various points of use. Valves and regulators are used to control the flow and pressure of the compressed air.

What is Compressed Air Used for?

Pneumatic tools, such as drills, grinders, nailers, staplers, and impact wrenches, are commonly powered by compressed air.

Additionally, compressed air is used in HVAC systems for ventilation and climate control, as well as in industrial processes like painting and sandblasting.

Advantages Of Compressed Air Energy Storage

Compressed air is an indispensable energy source that has proven reliable, versatile, and safe. It is very beneficial and an essential factor in our lives, from the celebratory balloons at birthdays to the air in the tires of our cars and bicycles.

Here are the advantages of compressed air energy storage in short:

- Energy efficient

- It’s safe and secure

- Low operating costs

- Improved productivity

- Cheaper power source

- Versatile tools and applications

Improved Productivity With Compressed Air Energy Efficiency

Compressed air might be used in the production of devices such as phones, tablets, or computers you are using to read this. But, they are certainly used in the operation of robotics arms on production lines in many industries

However, there are small compressors used for PC cleaning, especially for unclogging air vents, heat sinks, and fans.

Compared to electric power tools, pneumatic tools require much less maintenance, are nearly indestructible, and are energy-effective as well. They are suitable for tough applications and harsh environments.

On the other hand, electric power tools are not suitable for tough applications especially in steel mills and foundries due to the high temperatures and dirty surroundings.

Such an environment can lead to frequent electrical overloading and equipment malfunctioning due to overheating. I know that companies like Dewalt, and Makita have made power tools with heat sensors but, that doesn’t mean you become carefree.

Low Operating Costs

On-site power generation is made possible through compressed air, even though its production may be costly. Despite this expense, it is still a vital component of many manufacturing and industrial operations, as it offers low operating costs.

But, there is a catch if you wanna bring down the compressed air costs. I advise you to buy an energy-efficient air compressor. Make sure to do proper compressor maintenance.

Change the filters regularly, and use synthetic oil for your compressor if it’s oil-lubricated. Make a schedule for troubleshooting your compressor at regular intervals.

Another important thing I wanna mention to you is the compressor you gonna use depends on your type of work. If you have a workshop then the compressors with a 20-gallon and 30-gallon storage capacity are the best.

Always, look for HP, and a compressor with a high storage capacity. That means a compressor needs to run less often if it has a higher storage capacity. Such as compressors with 60-gallon or 80-gallon storage capacity.

Safety And Security

Compressed air is clean and non-toxic, making it suitable for applications where contamination is a concern. Additionally, compressed air systems are designed with safety features, such as pressure relief valves, pressure switches, and automatic shutdown mechanisms.

The air in the compressed state is a great way to store and transmit energy, as it is flexible, user-friendly, and relatively safe compared to other energy sources such as batteries and steam.

Batteries are massive and have a short life span, while steam is costly and difficult to handle as it can get too hot. In terms of cost efficiency, electricity is the better choice, yet compressed air still has its benefits.

Versatile Tools And Applications

In industrial, business, and home environments, air compression is widely utilized as a power source, although many people are unaware of its prevalence.

I have almost visited every industry plant that uses compressed air and observed their work with compressed air. Starting from manufacturing pneumatic tools, and operating robotics for a smooth workflow to healthcare, and the automotive industry.

Below I have discussed these industries and the applications of compressed air.

Real-world Examples: Industrial Applications of Compressed Air

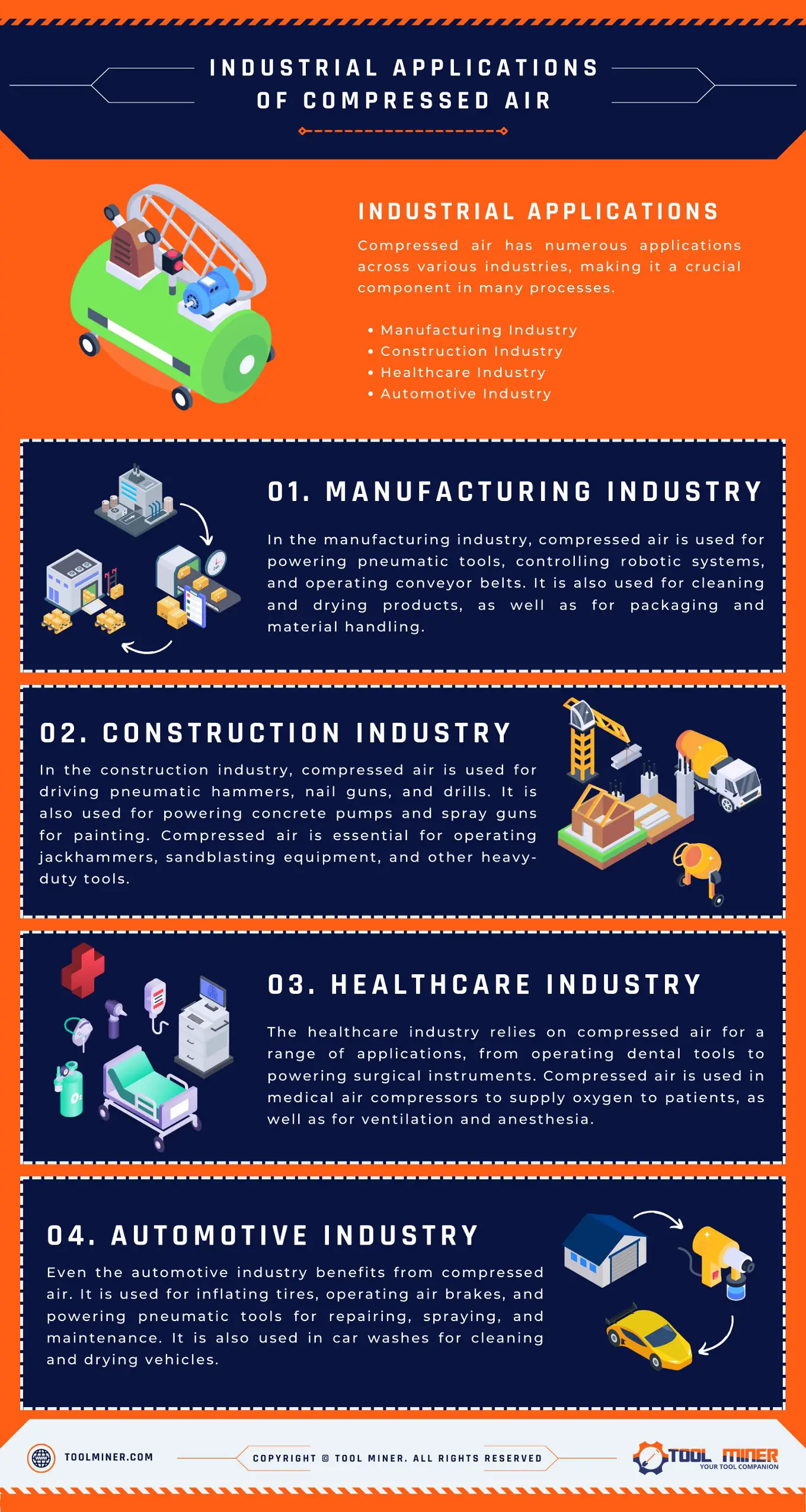

Compressed air has numerous applications across various industries, making it a crucial component in many processes.

Manufacturing Industry

In the manufacturing industry, compressed air is used for powering pneumatic tools, controlling robotic systems, and operating conveyor belts. It is also used for cleaning and drying products, as well as for packaging and material handling.

Construction Industry

In the construction industry, compressed air is used for driving pneumatic hammers, nail guns, and drills. It is also used for powering concrete pumps and spray guns for painting. Compressed air is essential for operating jackhammers, sandblasting equipment, and other heavy-duty tools.

Healthcare Industry

The healthcare industry relies on compressed air for a range of applications, from operating dental tools to powering surgical instruments.

Compressed air is used in medical air compressors to supply oxygen to patients, as well as for ventilation and anesthesia.

The Medical Oxygen System I saw in Hospital

It’s not that the oxygen pump was beside every patient. There was an elaborate pipeline system inside the walls that was connected to the cylinders in a special compressor chamber.

Each ward had a bed with a set of oxygen nozzles embedded inside walls. These nozzles supply oxygen to the patients. However, there are portable oxygen cylinders as well.

Automotive Industry

Even the automotive industry benefits from compressed air. It is used for inflating tires, operating air brakes, and powering pneumatic tools for repairing, spraying, and maintenance. It is also used in car washes for cleaning and drying vehicles.

Compressed Air Systems: Parts, Types, Storage, Usage, And Their Maintenance

Now, that was my tour of the industries and what I have seen. Here I am gonna explain how different parts of compressors or compressed air systems work simultaneously together.

Parts Of Compressed Air Systems

Compressed air systems consist of several Parts that work together to generate, store, and distribute compressed air. The main parts include the compressor, storage tank, air dryers, filters, and distribution network.

The compressor is the heart of the compressed air systems, responsible for compressing the air to the desired pressure. It is typically driven by an electric motor or a diesel engine. These compressors further have different parts that operate in conjunction.

The storage tank, also known as an air receiver, acts as a reservoir for the compressed air, allowing for a steady supply during peak demand.

Air dryers and filters are used to remove moisture, oil, and contaminants from the compressed air. This helps to prevent damage to downstream equipment and ensures the quality of the compressed air.

The distribution network consists of pipes, hoses, valves, and regulators that carry the compressed air to the points of use.

Types Of Compressors

There are several types of compressors available, each with its advantages and suitable applications.

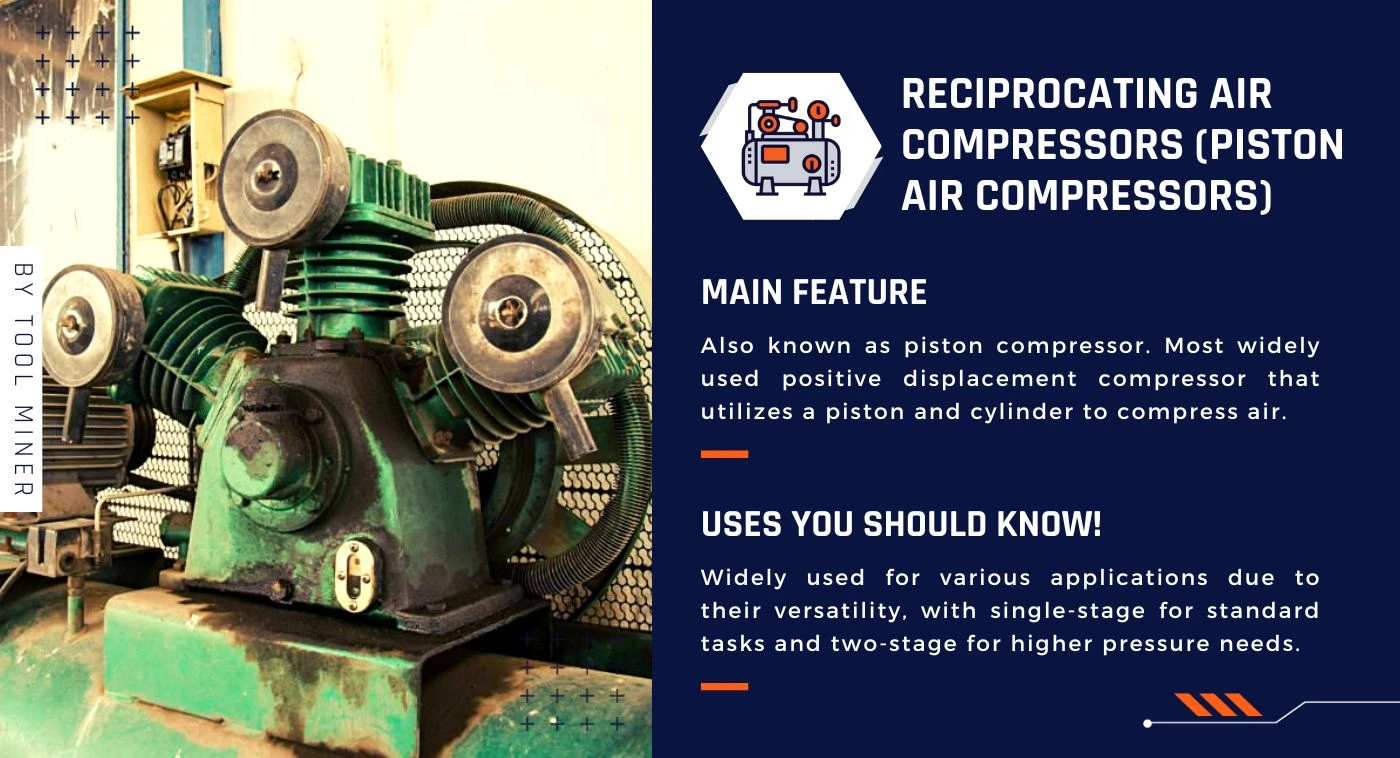

Reciprocating Compressors

Reciprocating compressors, also known as piston compressors, use reciprocating pistons to compress the air. They are commonly used in small-scale applications and are known for their compact size and affordability.

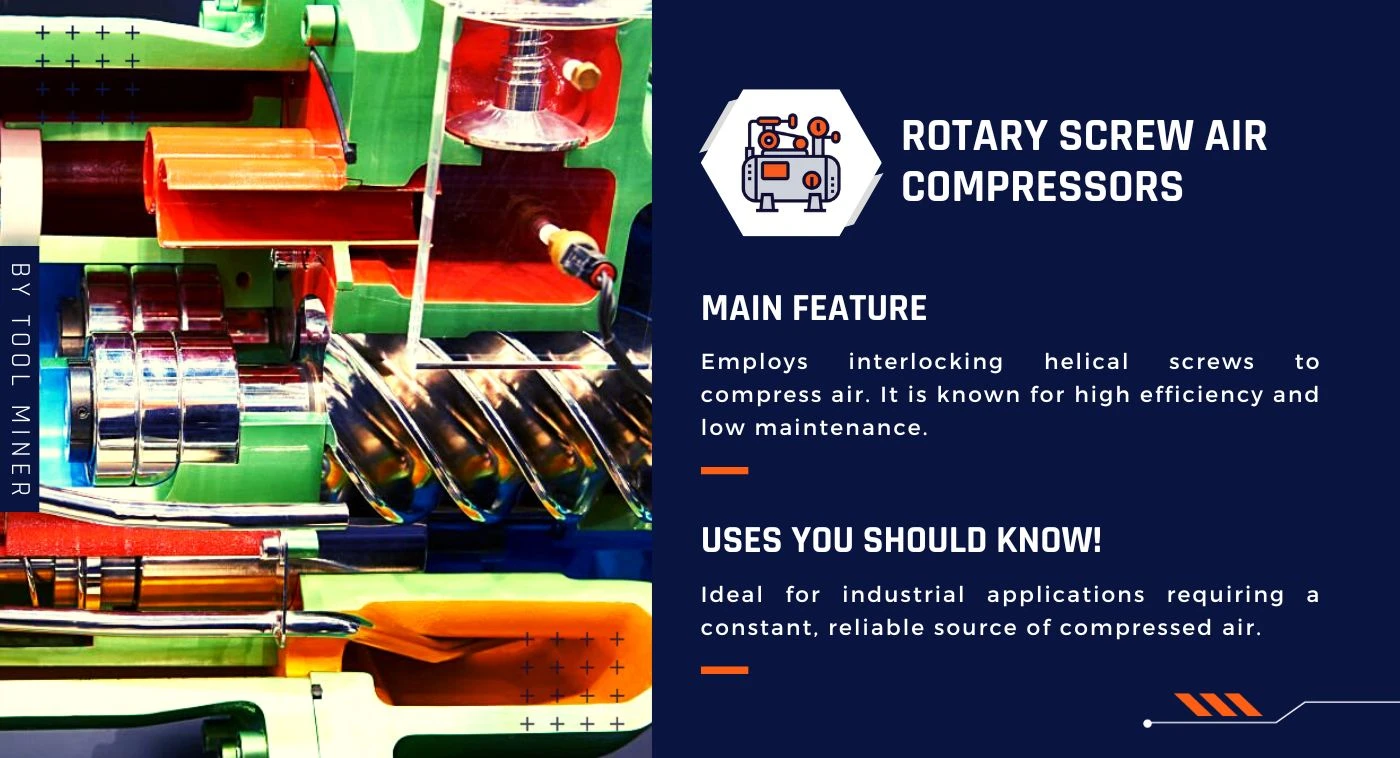

Rotary Screw Compressors

Rotary screw compressors are widely used in industrial applications due to their high efficiency and reliability. They use two intermeshing rotors to compress the air, providing a continuous supply of compressed air.

Rotary screw compressors are available in oil-injected and oil-free versions, depending on the purity requirements of the compressed air.

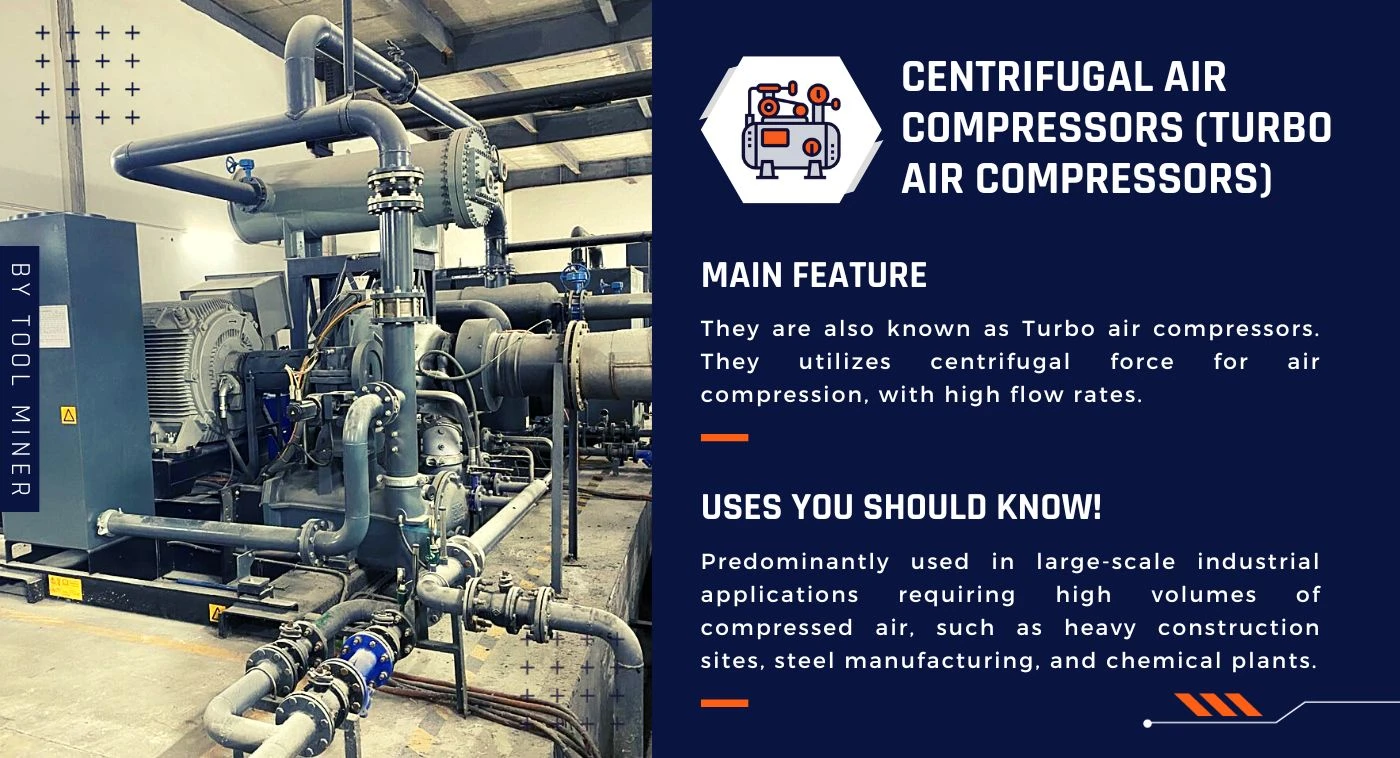

Centrifugal Compressors

Centrifugal compressors are used in large-scale applications that require high volumes of compressed air. They use a rotating impeller to accelerate the air, which is then compressed by diffusers.

Centrifugal compressors are known for their high flow rates and are commonly used in power plants, refineries, and other heavy industries.

Compressed Air Energy Storage And Distribution

Once the air is compressed, it is stored in a storage tank or air receiver. The storage tank acts as a buffer, allowing for a steady supply of compressed air during peak demand. It also helps to reduce the load on the compressor, prolonging its lifespan.

Compressed air is distributed through a network of pipes and hoses to various points of use. The distribution system should be designed to minimize pressure drops and ensure an even flow of compressed air.

Valves and regulators are used to control the flow and pressure of the compressed air, allowing for the precise operation of pneumatic tools and equipment.

Efficiency of Compressed Air Energy Storage Usage

Compressed air systems can consume a significant amount of energy, making energy efficiency an important consideration. There are several ways to improve the energy efficiency of compressed air systems.

One approach is to reduce leaks in the system, as even small leaks can lead to significant energy losses. Regular inspections and repairs of pipes, fittings, and valves can help to minimize leaks.

Proper sizing of compressors and other components is also important, as oversized equipment can lead to unnecessary energy consumption.

Additionally, using energy-efficient compressors and optimizing the operation of the system can further improve energy efficiency.

Variable speed drives can be used to match the output of the compressor to the demand, reducing energy consumption during periods of low demand.

Maintenance And Safety Considerations For Compressed Air Systems

Proper maintenance is essential to ensure the efficient and safe operation of compressed air systems.

Regular inspections, servicing, and repairing of compressors, air dryers, filters, and storage tanks are necessary to prevent breakdowns and maintain the quality of the compressed air.

Pressure relief valves should be installed to prevent over-pressurization, and automatic shutdown mechanisms should be in place to stop the system in the event of a malfunction.

Safety considerations should also be taken into account when working with compressed air systems. Workers should receive proper training on the safe use and maintenance of compressed air.

Because compressed hair is extremely dangerous if not used properly. You shouldn’t point it toward anyone else it can kill, blow your eye out of the socket, rupture your skin, etc.

That’s why I have designed a helpful infographic on the dangers of compressed air that’ll help you avoid these compressor problems.

Choosing The Right Compressed Air System For Your Needs

When choosing a compressed air system, it is important to consider your specific needs and requirements.

Factors to consider include the required pressure and flow rate, the type of pneumatic tools and equipment to be powered, and the quality of the compressed air.

It is also important to consider the lifecycle cost of the system, including energy consumption, maintenance, and operational costs. Investing in a high-quality and energy-efficient system may result in long-term cost savings.

Consulting with a compressed air specialist or supplier near you can help you determine the best system for your needs. They can assess your requirements and recommend the most suitable compressor type, storage capacity, and distribution system.

The Versatility And Importance Of Compressed Air

Compressed air is a powerful and versatile utility that plays a vital role in numerous industries. Its ability to power a wide range of tools and equipment makes it an essential component in the manufacturing, construction, healthcare, and automotive industries, among others.

Understanding how compressed air works, its history, advantages, and applications can help both professionals and curious individuals appreciate its importance.

By choosing the right compressed air system, maintaining it properly, and optimizing its energy efficiency, businesses can maximize the benefits of compressed air while minimizing costs.

Conclusion: The Fourth Utility

In conclusion, compressed air is more than just air under pressure. It is a valuable resource that drives innovation, efficiency, and productivity in various industries.

So, whether you’re using a pneumatic tool, enjoying the benefits of climate control, or receiving medical treatment, remember the power and versatility of compressed air.

It truly is the “Fourth Utility” that keeps the world moving forward.

Compressed Air FAQs

What Do You Mean by Compressed Air?

Compressed air is air that is pressurized and stored in tanks for various industrial and commercial applications.

What is Compressed Air Used for?

Compressed air is used for powering tools and machinery, inflating tires, cleaning, and even in medical devices like ventilators.

What is an Example of Compressed Air?

A common example is a balloon. When you inflate it, you’re compressing air into a smaller space. The energy stored in the compressed air is what makes the balloon fly when released.

Is Compressed Air Dry or Wet?

Compressed air is typically dry, but it can contain moisture that needs to be removed using air dryers or filters.

What Liquid is Compressed Air?

Compressed air is not a liquid; it’s a gas under pressure. Liquids can condense from moisture in compressed air. Compressed air cans have a liquid called difluoroethane.

Why is Compressed Air Used in Industry?

Compressed air is versatile and used in industry for powering tools, controlling machines, and conveying materials efficiently in production lines.

What Industry Uses the Most Compressed Air?

Industries like manufacturing, construction, automotive, and healthcare use significant amounts of compressed air in their operations. Just check my infographic for more specific info.

Is Compressed Air Dangerous?

Compressed air can be dangerous if mishandled, as it can cause injuries like cuts, burns, or even lung damage if blown directly into the body.

Is Compressed Air Flammable?

Compressed air itself is not flammable, but it can carry flammable substances if contaminated, or it can create a flammable atmosphere when concentrated, posing a fire risk.

Is Compressed Air Cold?

Compressed air can be cold when rapidly expanded, potentially causing frostbite if touched directly. especially it is caused by compressed air cans.

Does Compressed Air Expire?

Compressed air doesn’t expire, but the quality may degrade over time due to moisture or contamination.

Does Compressed Air Have Weight?

Compressed air does have weight because it contains molecules, but the weight is relatively small and typically measured in pounds or kilograms.