What is an Air Compressor Pressure Switch? [Parts, Types, Working 2024 Guide]

Understanding and knowing your machine is one great aspect of working smoothly. The same notion applies to air compressors.

When dealing with these buddies you need to watch out for different problems and maintain your air compressor parts. One such part is the air compressor pressure switch. Might be a small guy but works like a beast.

In today’s mining session, you and us going to learn the basics and complexities of pressure switches. Its different parts and their working mechanism. Some popular pressure switch types you can use.

What Is An Air Compressor Pressure Switch?

An air compressor pressure switch is a mechanical device. It relies upon air pressure to control the specific functions of an air compressor.

This simple tool completes the entire circuit of the air compressor. It further grants power to the motor as long as the system pressure is below the preset settings.

This little buddy holds immense importance. The pressure switch guides your compressor to when to start and when to stop. Most of the time when your air compressor gets busted and needs repair is due to a faulty pressure switch.

When the air tank reaches the required air pressure, the switch turns off the compressor. The switch also plays an important role in maintaining the pressure in your tank.

Air Compressor Pressure Switch Parts

Next are the main components of the pressure switch described below.

Auto/Off (Lever or Knob)

The first crucial component we are discussing is the Lever/Knob of the pressure switch. In some cases, there will be a difference depending on the type and brand of the pressure switch.

In some switches, a lever is present on the right or left side of the switch. While in some pressure switch types, you will have a red knob on the top. Both have a similar function of separating apart the contacts.

Terminals

Terminals are those regions where you should connect incoming and outgoing power cords. The terminal’s location varies with the type or brand of pressure switch you are using.

Contacts

Contacts are those components that are crafted with a conductive material. The material contained is 10% Nickel and 90% silver.

The contact’s primary function is to close the electrical circuit. It allows the power to flow toward the motor. When the contacts are apart, the circuit is incomplete, which results in motor shut-off.

Diaphragm

Up next in the component list is the diaphragm. The diaphragm is constructed with flexible material. The function of the Diaphragm is to control the contacts.

The flexible structure helps it push against the block as air pressure increases. When the required “Cut-Out Pressure” is attained, the diaphragm forces the contacts apart and shuts off the motor.

Pressure Relief Valve

Now, what is a pressure relief valve? As it turns out, it’s a type of valve that relieves head and line pressure. In simpler terms, it acts as a rescue back door.

If the pressure switch fails to cut off power to the motor for any reason. The compressed air pressure can reach a dangerous level in the tank and can cause an explosion.

For that reason, the PRV has an opening that activates when the pressure reaches a certain level. This depends on the design and mechanism of the air compressor.

The excessive amount of pressure in-tank vents out from the PRV opening. This process takes place at an enormous speed then the compressor can pump it into the tank. Thus, minimizing the pressure back to the normal state.

Adjustment Springs

The main operation of the adjustment spring is to increase or decrease the cut-in/cut-out pressure. Well, in some cases, there are pressure switch types that have a secondary spring. The “Secondary Spring” is smaller than the “Primary Spring”.

The function of the secondary spring is to only regulate the cut-out pressure without affecting the cut-in pressure settings.

3 Types of Pressure Switch

Moving on to the next area is the “Pressure Switch Types”. Here I am going to give you a brief lesson about the few popular pressure switch types. Their structure is with a diagram.

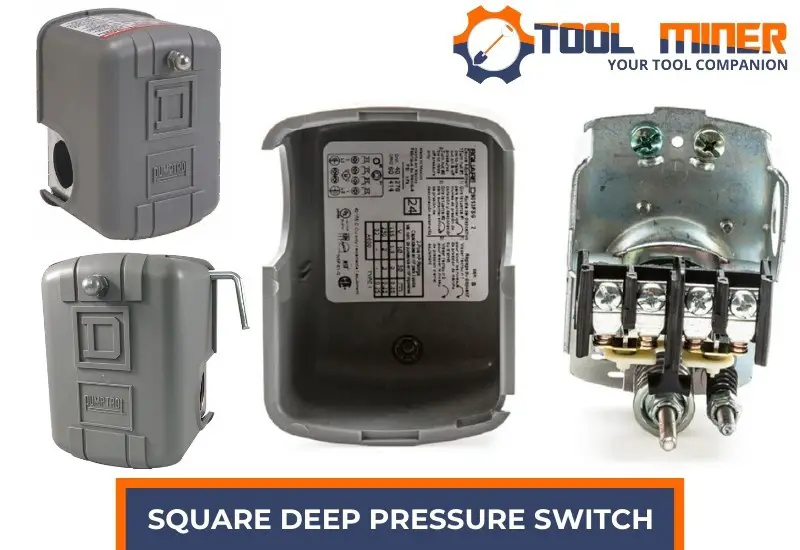

Square D Pressure Switch

The Square D Pressure Switch is utilized for controlling the well system. It turns the well pump on and off to maintain the water pressure under the preset level.

If the pressure falls to a certain level it starts the pump to gain the optimum level. If the pressure reaches a maximum set range, it shuts off the pump.

If an “uncontrolled pressure flow” occurs, it can cause the pressure to drop too low. The pressure switch immediately disables the pump until the problem is resolved.

To resolve the issue, you have to manually reset the switch. You can do it by holding the side lever on the switch until the water pressure is high enough.

The Square D Pressure Switch also prevents the pump from unnecessary use. Because excessive usage can cause an early breakdown of your pump.

Condor Pressure Switch

Now, the condor air compressor pressure switch is one of the most popular among folks who use air compressors. The primary function of Condor is the same as other pressure switch types. And it’s to maintain the pressure in the tank.

It has different models with different capacities and upgraded functions. Discussing all the types here will become boring. Also, it will take longer for you to ingest all the information.

So, to make it easier I am discussing with you only one model which is Condor MDR-2. I will write about the rest of the models in another post in the future.

The Condor MDR-2 pressure switch is usually utilized in a single-phase compressor. You can also use them in large compressors like 60-gallon or 80-gallon for providing signals to the control circuit.

Another fact that I’ll mention is that the MDR-2 has a built-in differential capability. This capability allows MDR-2 to have greater control over the cut-out pressure.

Let me end with an example. If we preset the cut-in pressure to 4 bar then you can adjust the cut-out pressure up to the range of 5.4 bar and 7.4 bar.

Hubbell Pressure Switch Or Furnace Pressure Switch

The third type of most popular pressure switch is the Hubbell pressure switch also known as the furnace pressure switch. Like Condor, the Hubbell pressure switch has different models with a wider range of features (PDF).

The primary function of all furnace switches is the same as usual. So, here I am going to cut to the chase and mention only one type of furnace switch such as the 69J Furnace switch.

The 69J is well-known in the market. As it grants flexibility to its user to build the pressure switch around the compressor, not the other way around.

Now in the Furnas pressure switch, you can adjust the unloader valve on both sides. But, also you can rotate it in any of eight different directions. This attribute helps in quicker assembly and shorter tubing.

Another aspect that I would like to mention is the “Bottom Entry Frame”. The frame is designed with built-in clamping strain relief. This relief provides faster assembly.

Further down the line, I want to reveal to you another curious fact. The 69J has thousands of variations that provide maximum flexibility at a lower cost.

Because of the consent of CCC, CE, and other major world organizations, the 69J model has become a worldwide selling product.

WHat are Pressure Switch Settings?

Right pressure switch settings are the most basic and crucial step of the compressor and switch working. These settings are utilized by both small piston compressors and large industrial compressors.

In small compressors, the pressure is set on the pressure switch. While in larger compressors, it’s a bit different. The pressure setup is done on the central compressor controller. But, the concept remains the same.

Another point I wanted to discuss was pressure switch setting types. Beforehand you already heard about the Cut In and Cut Out Terms. Let me describe it to you.

Cut-In Cut-Out Pressure

The compressors operate on two pressure set points (cut-in and cut-out). These are the two pressure points on which the compressor starts and stops.

When the compressor reaches the cut-out point it stops. That’s why the cut-out pressure is also known as the maximum pressure.

When the compressor reaches or drops back to the cut-in pressure it starts again. Thus, the cut-in pressure is also known as the minimum pressure.

Differential Pressure in Pressure Switch (Pressure Band)

The cut-in pressure will always be lower than the cut-out pressure. This difference between cut-in and cut-out pressure is called Differential Pressure. Another term used for differential pressure is pressure band.

A rule of thumb you should memorize is that the differential pressure will always be at least 1 bar. Do not adjust the pressure difference between the cut-in and cut-out if it’s too low. If you do then the compressor will start and stop at a rapid speed. This results in a lot of damage Such as:

The Damage

- It will put considerable pressure on the motor and the motor will get burned

- The other compressor components will also be under excessive pressure

- The pressure switch will get damaged in the process

How Does an Air Compressor Pressure Switch Work?

I was thinking of describing the working mechanism of the pressure switch briefly. Up till now, you have already been familiarized with different terms.

Pressure Switch Air-lines

The pressure switch utilizes airlines to monitor the pressurized air as it travels to and from your air compressor. Every switch has a particular component that works when pressure is exerted. The most common part is the Diaphragm.

Working of Diaphragm

I have already discussed, that what a diaphragm is and the function it performs. You can look at the “Parts” section. Here, I am only detailing the working process.

When the air pressure in your tank increases. It builds up a backward pressure which causes deformation of the diaphragm. Due to this deformation, movement in the pressure switch takes place.

When the diaphragm deforms enough then it will break the switch’s inner contact. This results in a power flow stoppage to the motor circuit of the compressor. It also blocks your air compressor from further pressurizing the air in the tank.

Consistent air pressure with a precise volume will keep the diaphragm deformed. But, when the pressure in the tank falls to a certain point, the diaphragm will return to its original form.

Once the cut-in pressure reaches the specified level. An internal mechanism inside the diaphragm deforms it into the opposite position. Thus, closing the circuit as well as starting the motor again.

Continuation

This process continues as long as compressed air is being used. The circuit shuts down when the external power source is cut off or if there’s a problem.

In some situations, you have to replace and wire the pressure switch on the air compressor. While in some cases you only have to adjust it.

Some of the problems are related to leakages while some are related to wiring. Well, what I experienced most were cases of pressure switch wiring.

Air Compressor Pressure Switch FAQs

Q: What is pressure switch?

Ans: A pressure switch typically is an electronic or mechanical device that is used for measuring or maintaining the pressure of a fluid or gas medium. The pressure switch typically turns on or off the application when the pressure reaches the set limit. The switch works for both limits high and low. It is found in industrial tools like air compressors, pumps, and hydraulic, and HVAC systems.

Q: Do I need a pressure switch on my air compressor?

Ans: An air compressor pressure switch plays an essential role in your compressor’s overall working. It monitors, maintains, and regulates the pressure inside your compressor. And if the pressure exceeds the set threshold it turns on/off the compressor to avoid any damage. So, you need to properly maintain it, and if gets busted then replace it with a new one.

Q: Where to buy pressure switch for air compressor?

Ans: You can buy a good compatible air compressor pressure switch from your nearby electronics store or you can go look on Amazon. Because Amazon is the most trusted place when it comes to buying these types of tools and accessories.

Q: How to tell if pressure switch is not working?

Ans: Well, if everything is doing fine the compressor, pressure switch, or other parts have no issue and still, the pressure switch is not working. Then the problem is with cut-in pressure. It happens when the tank pressure is beyond your switch’s cut-in pressure. So, try reducing the tank pressure.

i have craftsman air compressor #919167620, 150psi, 120v, oil-less. i am changing pressure switch. 2 green wires go to 2 screws to metal backing plate. no problem. i then have 2 white wires that have spade connectors, connecting to each other. again no problem. now, i have 4 spade terminals below the pressure spring. 1 top left, 1 bottom left 1 top right, 1 bottom right. i marked the 2 wires(left and right). i forgot to note whether the 2 wires go on top or bottom terminals. my switch is a condor-usa pressure switch #034-0184rp. would really appreciate help, do not want get them wrong and smoke the motor.

Well, that’s the Powermate Vx Pressure switch. It’s an MDR 11 switch. So, here is the Manual that’ll help you out.

Condor MDR 11 Pressure Switch Wiring & Adjustment